28 Quality Control Survey Questions for Accurate Feedback

Discover 25 quality control survey questions to enhance your processes. Improve results with these expert-tested quality control questions.

You know what everyone wants? Fewer defects, better products, and customers who rave about your quality. That's where quality control surveys swoop in like superheroes for your business. These mighty questionnaires don't just catch mistakes before they snowball; they pack crucial data you can use to improve product quality, crush those costly returns, gather that coveted ISO 9001 feedback, and collect fuel for your continuous improvement engine. Let's break down the types of quality control surveys, when to deploy each, real-world questions you can steal, plus expert best practices to make every response count.

Customer Satisfaction (CSAT) Quality Control Survey

Why & When to Use

Craving the real scoop on what customers think? You need a CSAT quality control survey. These shiny tools are perfect for capturing honest-to-goodness, real-time customer feedback—like an espresso shot of insight right after your customer has interacted with your product or service.

Drop these surveys in after a purchase or support call, and you'll quickly discover if your product's field performance matches your team's promises. Want an instant pulse-check on customer perception of quality? CSAT is your go-to.

Here's the thing: CSAT answers can * Give you early warnings before a costly product recall * Support those bold marketing claims (“best widget ever!”) * Tie directly to your Net Promoter Score (NPS) for full-circle feedback

If you want both the sweet and sour of your product’s quality, you’ll want the customer’s perspective straight from the source.

5 Sample Questions

On a scale of 1-5, how satisfied are you with the overall quality of the product you received?

Did the product meet the quality expectations set by our advertising? (Yes/No)

Which single quality attribute (durability, appearance, functionality, packaging) needs the most improvement?

How likely are you to purchase from us again based on this product’s quality? (0-10)

Please describe any defects or inconsistencies you noticed.

One cheeky tip: Always dig deep with at least one open-ended question—your best ideas often live in those extra comments.

Embedding strategically placed “trap” or consistency-check questions in CSAT and quality-control surveys significantly improves data reliability by flagging inattentive or careless responses Data Use: An evaluation of quality‑control questions

How to Create a Survey with HeySurvey in 3 Easy Steps

Ready to get started with your own survey? Follow these simple steps to create, customize, and publish your survey using HeySurvey. If you’d like to jump-start your work, you can open a ready-made template by clicking the button below these instructions.

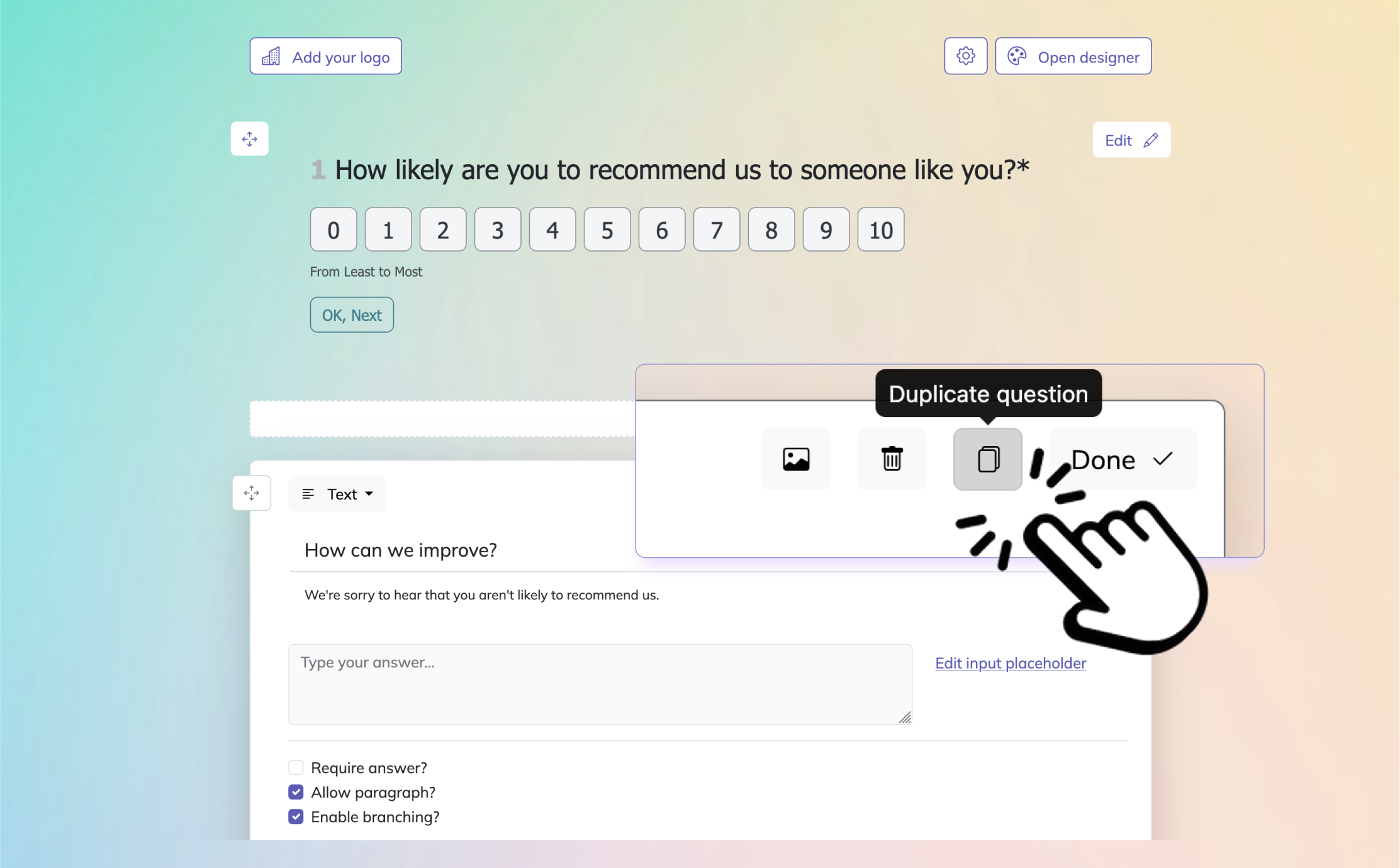

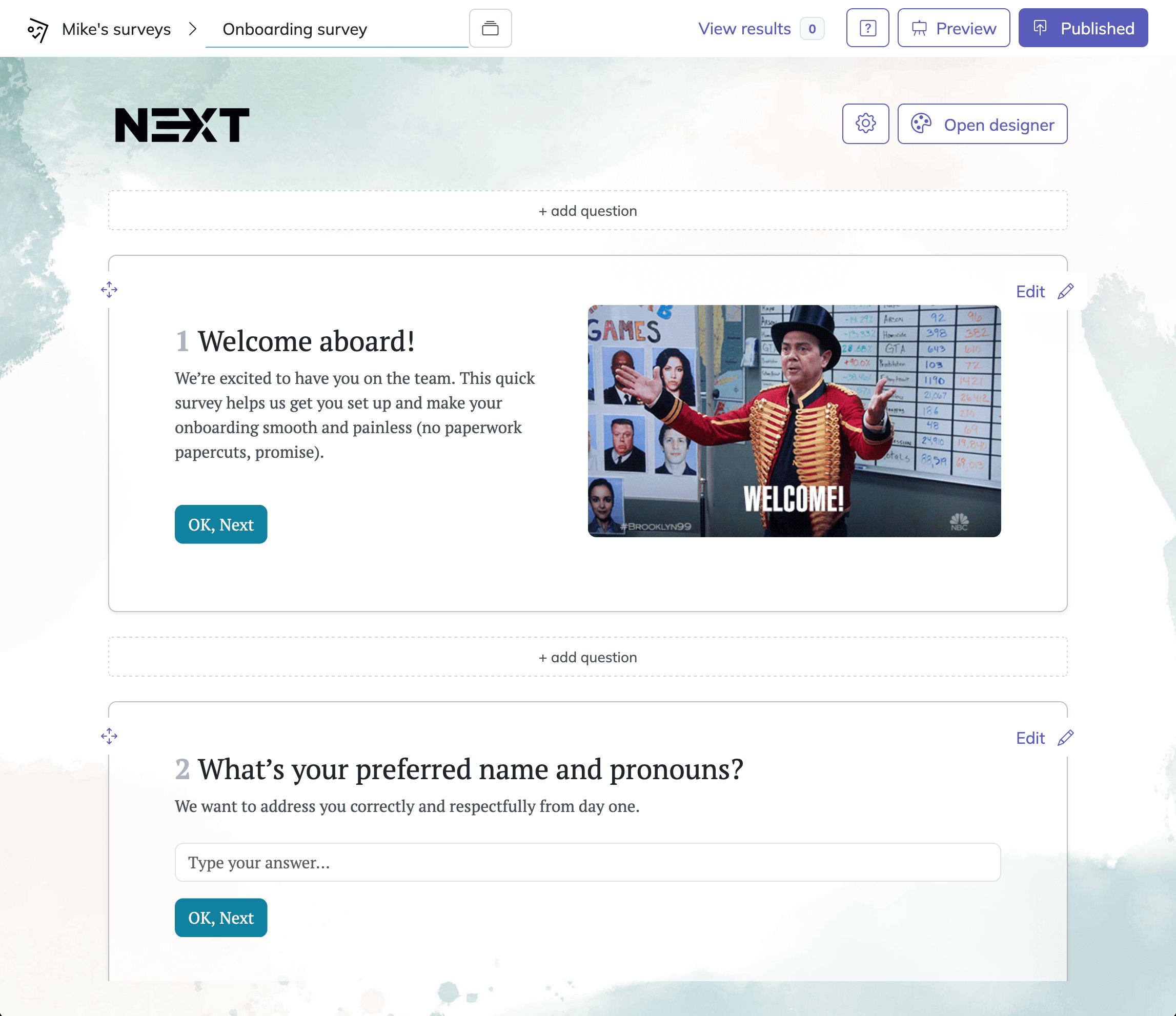

1. Create a New Survey

- Click on “Use Template” (or choose “Create New Survey” from your dashboard if you want to start from scratch).

- The Survey Editor will open. You can give your survey an internal name for easy organization.

2. Add Your Questions

- Click “Add Question” at the top or between existing questions.

- Choose the type of question you want (e.g., Multiple Choice, Scale, Text).

- Enter your question text, adjust settings, and add images or descriptions as needed.

- Repeat this process to include all the questions you need for your survey.

3. Publish Your Survey

- When your survey is ready, click “Preview” to see how it will look to respondents.

- Make any final adjustments in the Designer Sidebar (colors, fonts, layout) if desired.

- Click “Publish”, then create or sign in to your HeySurvey account (required for publishing).

- You’ll receive a shareable link and the option to embed your survey on a website.

Bonus Steps for a More Professional Survey

Apply Your Branding:

Open the Designer Sidebar to upload your logo, change colors, adjust fonts, or add a background image for a branded look.Define Survey Settings:

In the Settings Panel, you can set a start/end date, response limits, redirect URL after completion, or allow respondents to see results.Add Logic and Branching:

Use branching to direct respondents to specific questions or unique endings based on their answers, creating a personalized experience.

Once you’re ready to begin, simply click the button below to open this template and start creating your survey!

Need more help? Scroll down for a full guide to HeySurvey’s features and customization options.

Product Quality Inspection Survey (Internal Audits)

Why & When to Use

For those who live and breathe quality, the internal audit survey is like a trusty checklist. These surveys are built especially for QC inspectors on the factory floor, who want to catch non-conforming products before they slip through the cracks.

Deploy inspection surveys during in-process or final product inspections. Not only do you prevent the accidental shipping of lemons, but you also build a foundation for solid statistical process control (SPC).

With a quality inspection survey, you’ll always know if batches are up to spec (and up to snuff).

On top of that, you get to: * Lock down regulatory compliance * Collect hard data that pushes continuous improvement * Initiate corrective actions with zero fuss

Busy? This approach keeps your team focused on the numbers that matter, like defect rates and critical pass/fail criteria.

5 Sample Questions

Were all dimensional tolerances within the specified limits? (Yes/No)

How many visual defects were observed per 100 units?

Did packaging pass drop-test requirements? (Pass/Fail)

Rate the overall production batch quality from 1 (poor) to 5 (excellent).

List any corrective actions initiated during this inspection.

Remember, every “yes”—or “fail”—here helps you eliminate non-conforming products before they become very expensive mistakes.

Including at least one open‑ended question in quality control surveys significantly enhances engagement and yields richer insights than relying solely on closed-ended questions (source)

Employee Self-Inspection Checklist Survey

Why & When to Use

Feeling outnumbered by process problems? Grab the self-inspection checklist as your secret weapon. Handing accountability to your operators helps boost morale, reduce those annoying bottlenecks, and send quality issues packing.

This approach is perfect for lean or Six Sigma environments. It's fast, empowering, and requires zero paperwork headaches. Operators fill out these surveys at the end of each shift or before moving their work downstream.

Here's why this rocks: * You foster ownership of quality * Detect issues before they snowball * Build quality at every workstation, every shift

Plus, self-checklists turn each employee into a quality champion, all while freeing up your quality inspectors for the big-picture stuff.

5 Sample Questions

Did you verify torque values for all fasteners? (Yes/No)

Was the workstation cleaned and organized after the task? (Yes/No)

Rate your confidence that this unit meets quality standards (1-5).

Were any deviations from SOP detected? (Checkbox: None / Minor / Major)

Describe any tools or resources you lacked to complete the job to spec.

As a bonus, people secretly love getting to check off boxes—it makes them feel accomplished (and makes quality management way easier).

Supplier Quality Assurance (SQA) Survey

Why & When to Use

Ready to separate superstar suppliers from the duds? The Supplier Quality Assurance survey is built for you. You need these for both onboarding new suppliers and doing annual or quarterly check-ups on the familiar faces.

Here’s the scoop: SQA surveys keep your multi-tier supply chain in check. You stay on top of requirements for certifications like ISO 9001 or IATF 16949.

If your supplier is up to the challenge, fantastic. If not, you’ll know before you have a big problem on your hands.

With this survey, you’ll: * Measure supplier defect rates and timeliness * Confirm their quality management systems * Surface their commitment to continuous improvement

Plus, it doubles as documentation for your own audits—making you look sharp, organized, and always two steps ahead.

5 Sample Questions

What is your current defect rate (PPM) for delivered components?

Do you maintain a certified ISO 9001 or IATF 16949 QMS? (Yes/No)

How quickly can you implement corrective actions after a non-conformance report? (Days)

Rate your on-time delivery performance over the past 12 months (1-5).

Provide evidence of continuous improvement initiatives completed in the last year.

Choosing the right supplier often comes down to their answers on this list—and yes, a little playful pressure goes a long way!

A study of a steel pipe manufacturer in India found that supplier evaluation significantly improves process performance, with delivery reliability and relationship management being more influential than quality or cost. source

Post-Implementation Quality Audit Survey (Services & Projects)

Why & When to Use

Launching a killer software, completing a massive installation, or just finished a consulting gig? Don’t walk away yet. A post-implementation quality audit reveals if the delivered solution really matches what's on your contract (and your customer’s dream sheet).

Send these surveys right after the hand-off. You’ll measure if implementation quality matches expectations, surfaces any punch-list items, and captures lessons for next time.

This tool helps you: * Lock down contract compliance * Catch lingering quality problems before they turn to complaints * Fuel your team’s process for continuous learning

Here’s your chance to really check if work meets the highest standards—and show the customer you don’t just meet expectations, you beat them.

5 Sample Questions

Did the delivered solution meet all defined acceptance criteria? (Yes/No)

Rate the workmanship/professionalism observed during implementation (1-5).

Were project milestones achieved without quality-related delays? (Yes/No)

Identify any outstanding punch-list items affecting quality.

How confident are you that the solution will perform reliably for the next 12 months? (0-10)

Whether it’s a hospital wing or an app rollout, these survey questions help ensure your service or project quality truly delivers.

Return & Defect Analysis Survey

Why & When to Use

Nothing stings like a product comeback. But every return has a story—and your defect analysis survey is how you capture it. Whether filled out by the customer or your service tech, this survey is gold for the engineering, warranty, and design teams.

Pop it right after a return or repair event. The data pinpoints root causes so you can prioritize fixes, reduce warranty costs, and stop defect echoes.

With this smart tool, you’re able to: * Track repeat defects you’d otherwise miss * Collect top-notch evidence for engineering * Prove to your warranty manager that, yes, it is always the gasket

Plus, you’ll find that customers love their chance to vent—and you really want that feedback, warts and all.

5 Sample Questions

What was the primary reason for returning the product? (Dropdown list)

How long did the product function before the defect occurred? (Days/Weeks)

Did the defect pose any safety risk? (Yes/No)

Have you experienced similar issues with our products in the past? (Yes/No)

Attach photos or descriptions of the defect for engineering review.

Every answer here speeds up quality investigations—and makes your next product launch nearly bulletproof.

Continuous Improvement Feedback Survey (Kaizen Events)

Why & When to Use

Picture this: A bunch of energized employees, sticky notes everywhere, everyone tossing out ideas. That’s a kaizen event in action. But your real continuous improvement magic happens after, with feedback surveys that scoop up all those golden ideas.

You should send these surveys after any blitz or monthly quality roundtable. The goal? Find out what’s working, what’s not, and keep that improvement engine roaring.

You get to: * Pinpoint waste and quality defects at the source * Hunt down fast wins to boost morale * Ask what training (or donuts) would help the team

On top of that, you’ll learn which management moves actually support your quality targets. Sometimes, the best tips come from people who don’t love meetings but do love ticking boxes.

5 Sample Questions

Which process step currently contributes most to quality defects?

Rate the effectiveness of recent quality improvements (1-5).

What additional training would help you improve quality output?

Suggest one quick win that could reduce rework this week.

How well do you feel management supports quality initiatives? (0-10)

If you want a steady pipeline of continuous improvement data, make feedback surveys a regular habit.

Quality Control Survey Best Practices – Dos & Don’ts

Successful quality control surveys are like great recipes—you need the right mix, delivered in the right way. Keep your survey questions laser-focused on what's measurable, so your results lead straight to action, not head-scratching.

Here’s what you want to do: * Align every question with a measurable QC metric (think: CPK, defect rate, CSAT)

Blend a mix of closed-ended, scaled, and open-ended questions for rich, actionable info

Pilot test your surveys on a small group to check for clarity (and catch confusing wording early)

Automate those survey responses to your CAPA and reporting systems so you’re saving time

But here’s what you want to skip: * Overloading your respondents—short, sweet, and on-point always wins

Using language that makes defects sound scary or embarrassing (honest feedback wins)

Cramming in every possible objective—focus each survey for the sharpest analysis

On top of that: * Use checklists and templates! (Everyone loves a solid quality checklist or inspection survey template)

- Remember, a well-built defect analysis questionnaire is pure gold for your continuous improvement crew

It’s all about asking the right things at the right time—without asking for the moon.

Hey, whether it’s boosting your manufacturing, fine-tuning your service, or just showing the boss how quality numbers don’t lie, these quality control survey strategies are the ticket. Armed with these proven types, killer questions, and best practices, you’ll squash defects, delight customers, and keep your improvement wheels spinning fast. Plus, with tools like HeySurvey (free, forever), you can run top-notch quality control surveys without ever worrying about “premium” features. Time to level up your quality game!

Related Business Survey Surveys

28 Nonresponse vs Voluntary Response Survey Questions Explained

Explore 25 sample nonresponse vs voluntary response survey questions, understand key differences,...

29 Essential SWOT Survey Questions for Strategic Insights

Discover 25+ expert SWOT survey questions designed to capture strengths, weaknesses, opportunitie...

28 Quality Assurance Survey Questions to Improve Performance

Discover 25 top quality assurance survey questions to improve product quality and customer satisf...